Simulation

Service Description

With the rapid increases in system complexities, simple mathematical modelling is often no longer sufficient to verify that the design requirements have been met. Performance of the design is also normally impacted when under pressure or in a fallback scenario which static modelling often over-simplifies the flow-on effects. Simulation modelling is now a baseline requirement for any informed design process.

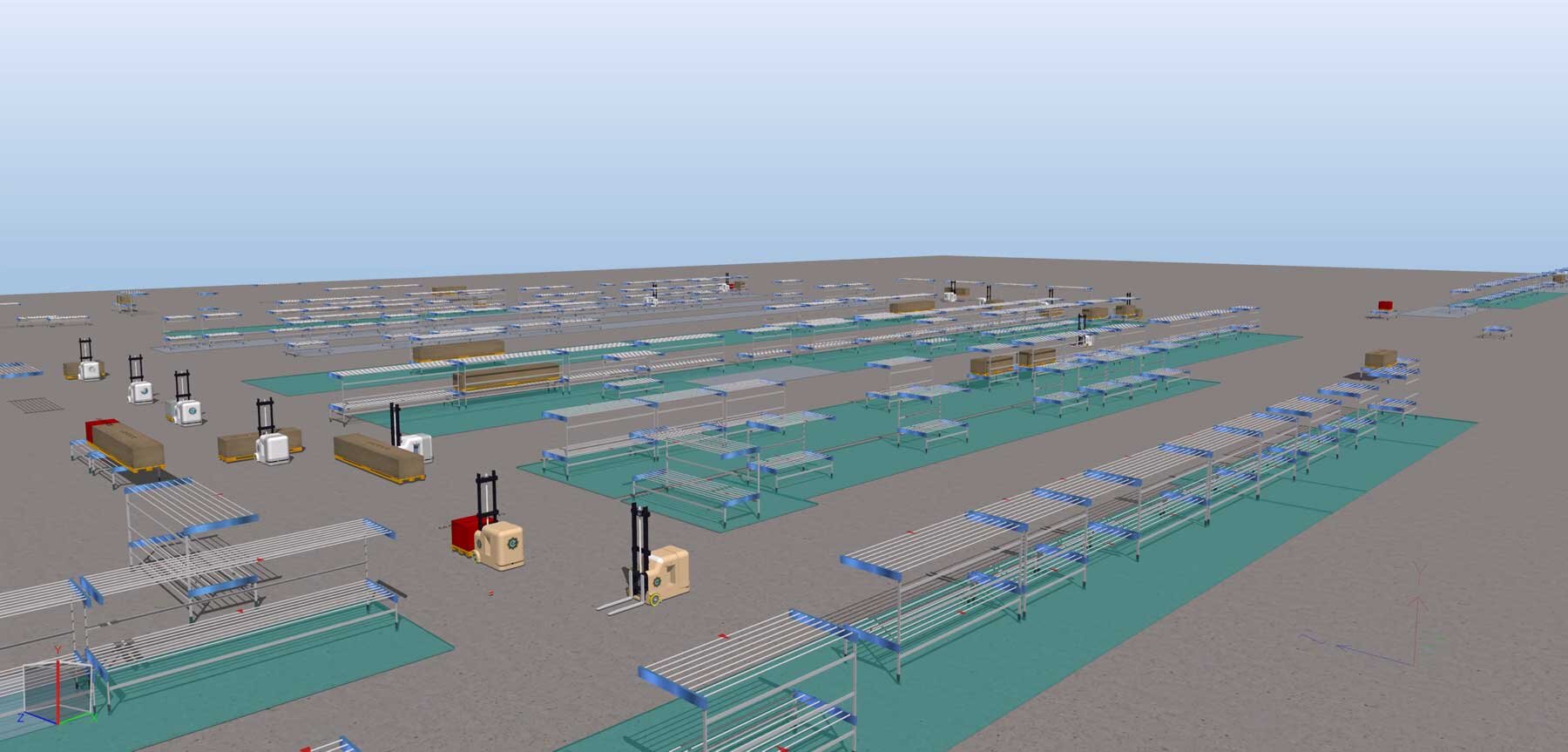

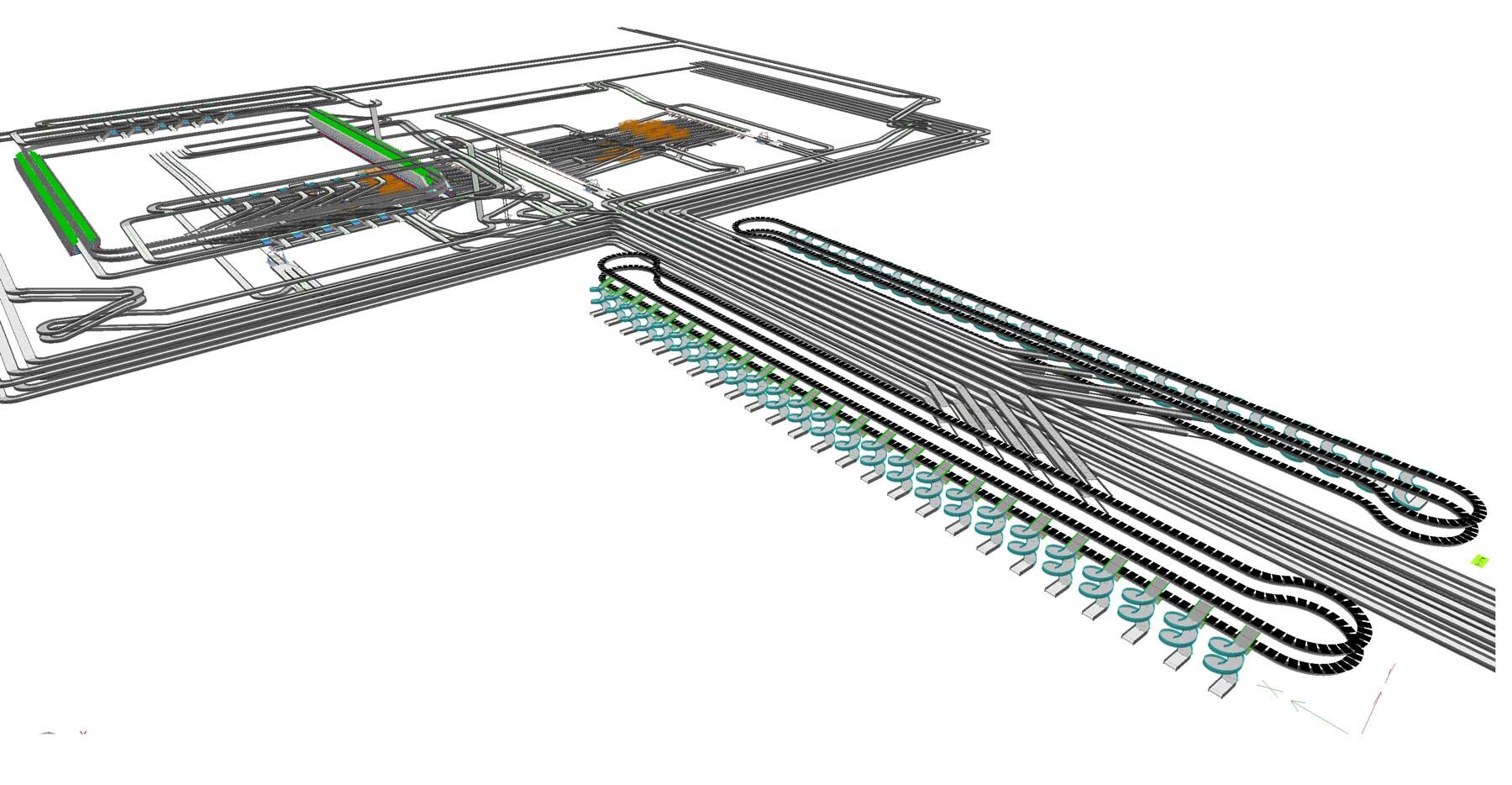

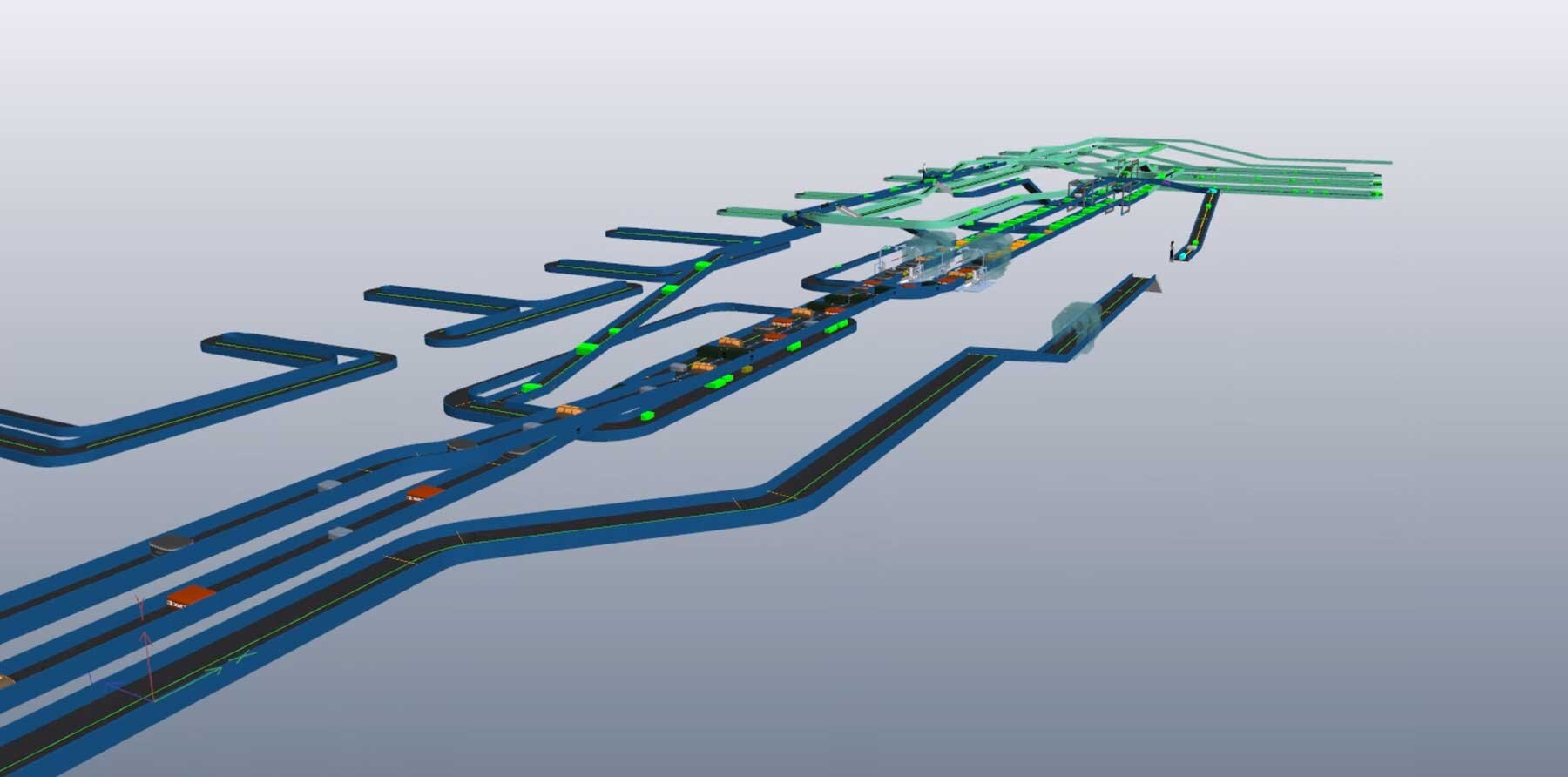

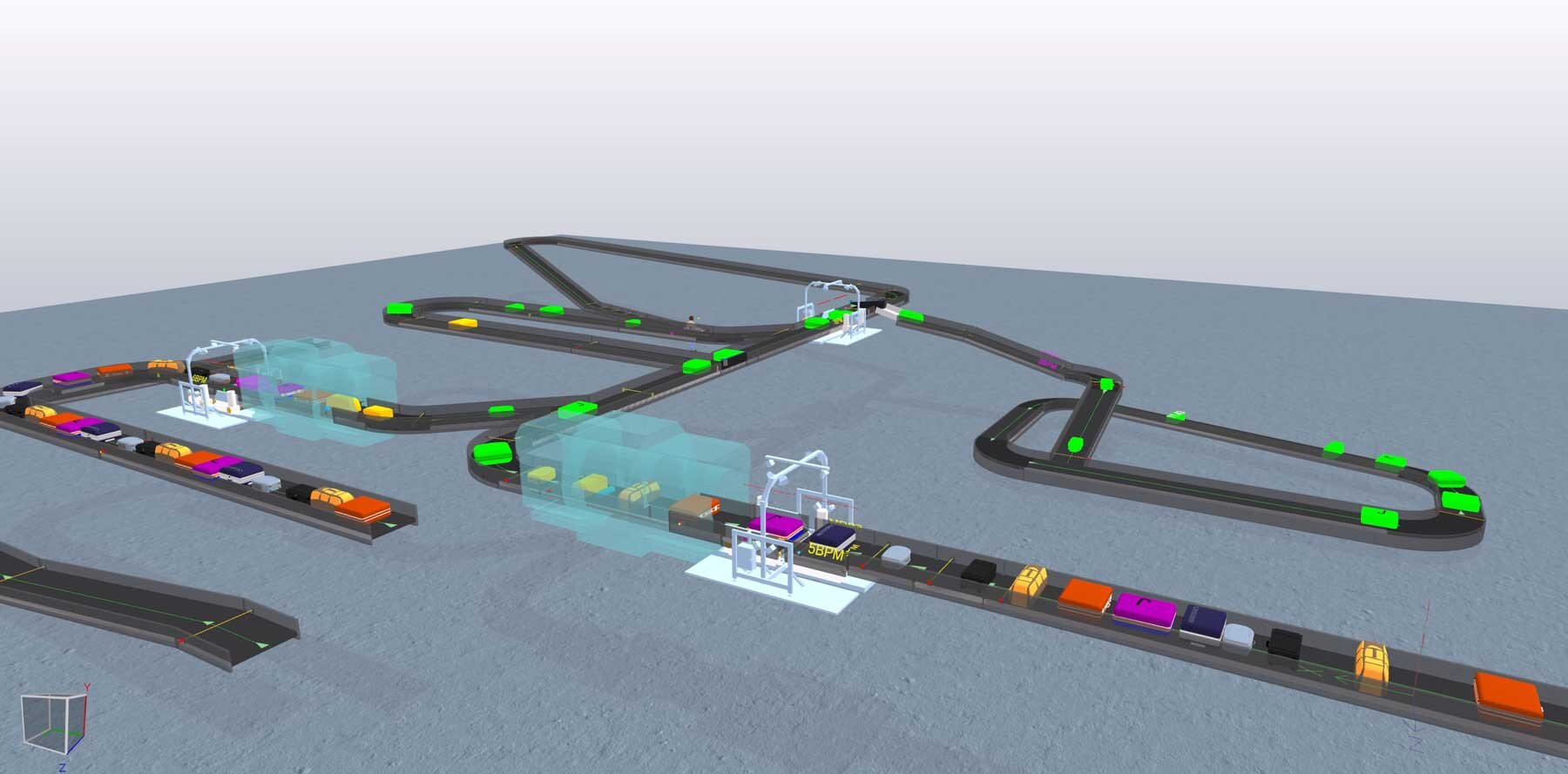

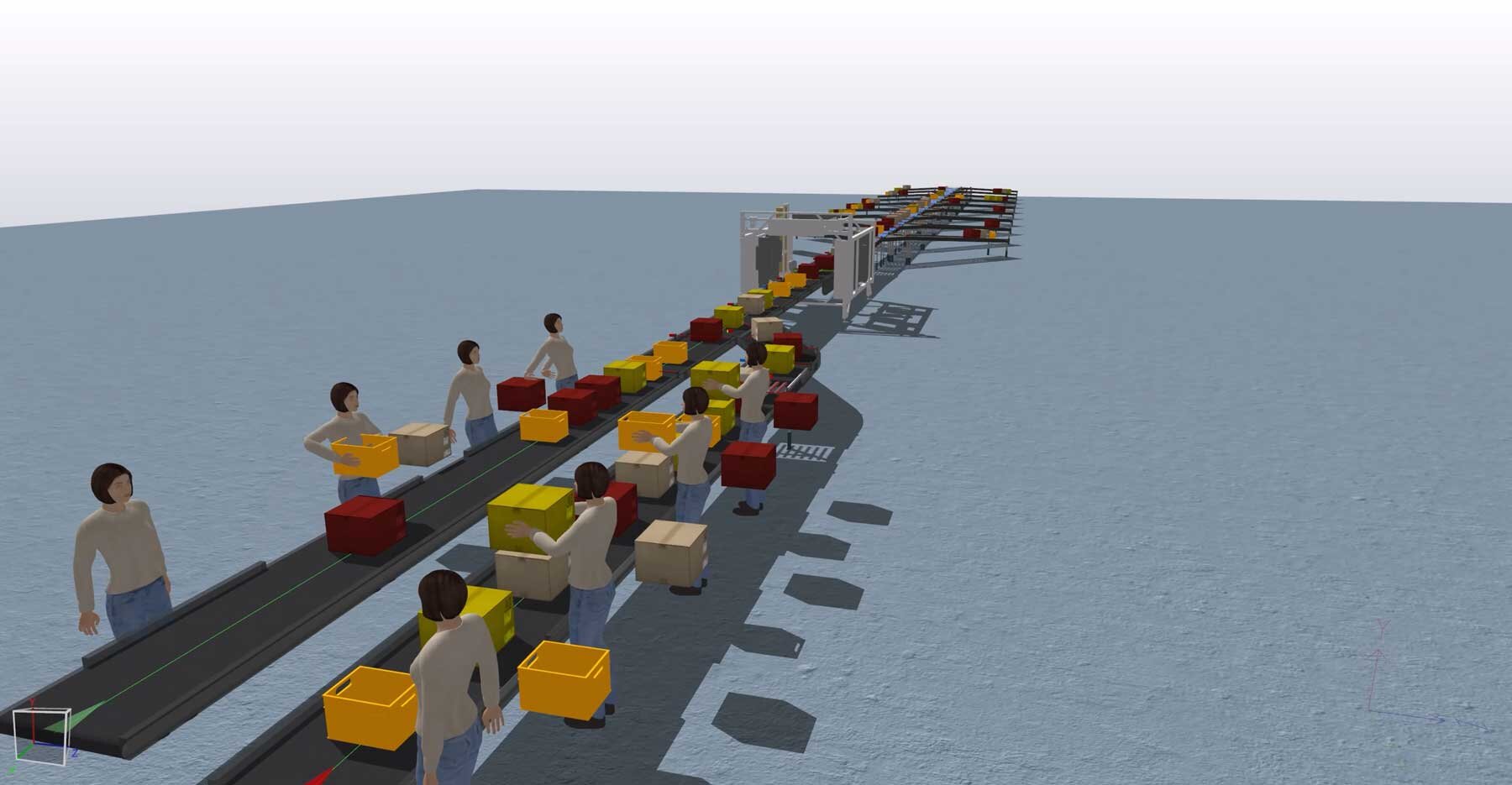

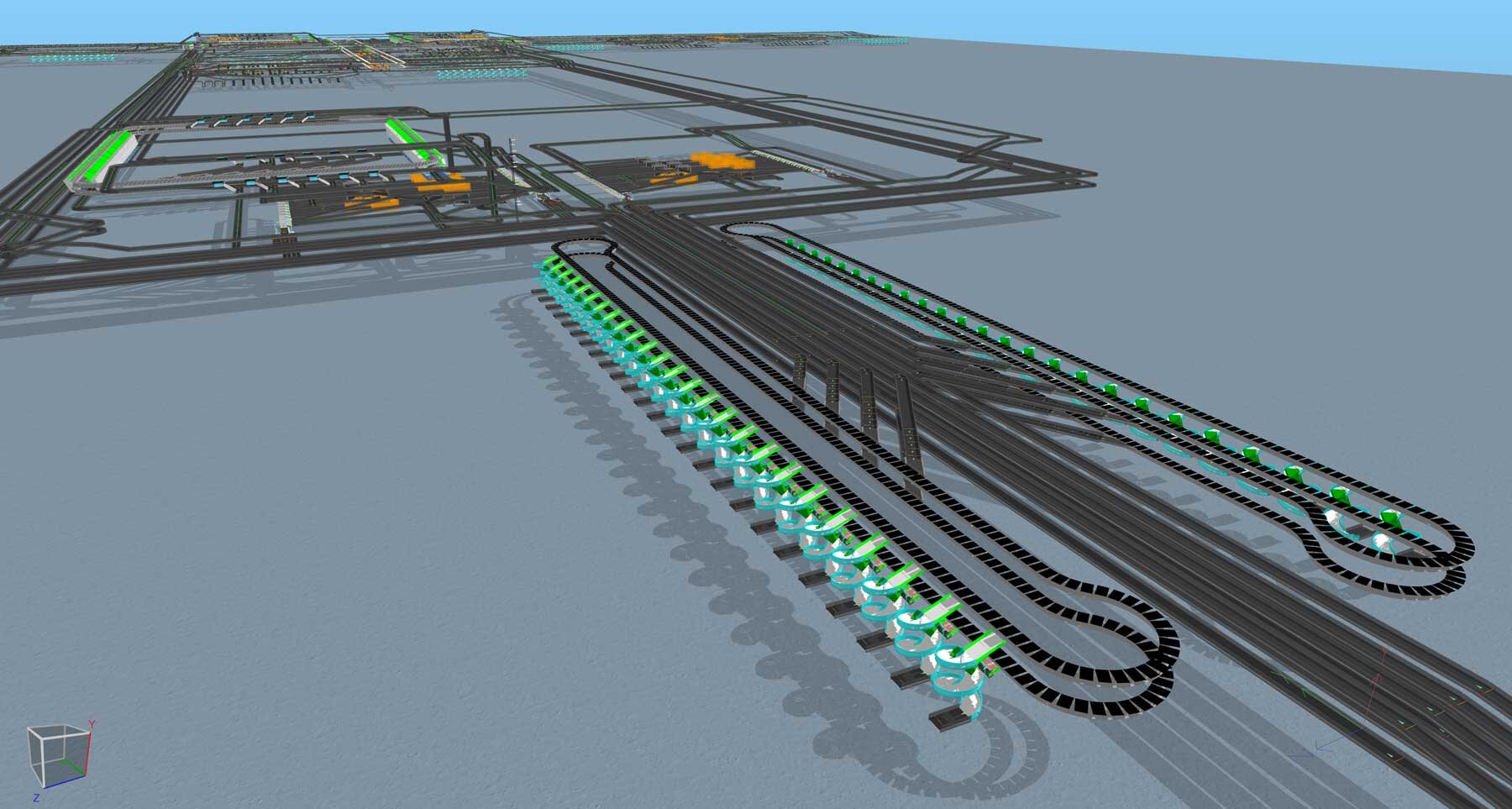

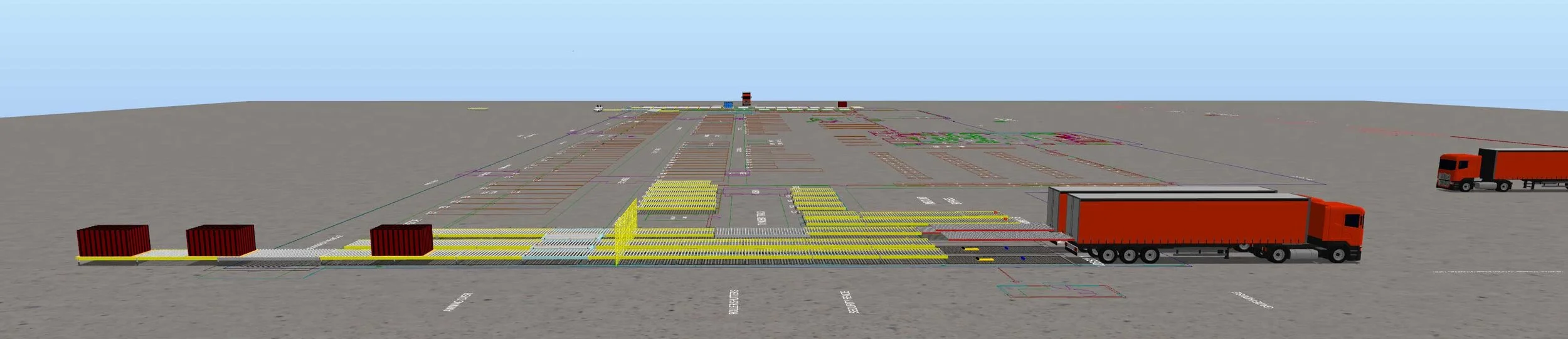

AvLogix’ simulation engineers utilise detailed 3D models to simulate every aspect of the system as designed, including (and potentially most importantly) the interfaces to other systems and/or manual interrelated processes. Using these complex engines, the team is able to simulate the designs likely operational performance and then fine‐tune the design to ensure that the solution achieves the best results.

Once the base requirements have been developed, we then expand the simulation models to run scenario tests to ensure that system performance requirements can still be met with varied inputs and constraints. This provides valuable insight into what our clients can expect under particular fallback scenarios and will provide the basis for business continuity planning for operations.

These simulations are very valuable during planning phases of a project to ensure that the proposed design meets the expectation of all stakeholders. The simulation model can incorporate the building architectural design and then incorporate Virtual Reality augmentation to dramatically improve the ability to get the message across quickly and accurately, particularly to people unfamiliar with the automation equipment.

AvLogix’ engineers are also able to extend the simulation models to emulate the equipment that will be installed if desired, allowing us to evaluate a contractor’s designed software prior to installation on site.